Ito Group is a multinational Engineering, Service, and Sales company focused on precision assembly of electronics.

Engineering is the core of what we do, and we stay focused on the practical application of technology to solving modern manufacturing problems. Our corporate mission is literally improve the efficiency of our partners’ operations, and we take this mission seriously. We understand that our partners are experts in their own rights — many times exceeding our own expertise in many ways in many fields. But we also know that time is a resource that no company has enough of, so we concentrate on providing engineering support in our niche, saving our partners’ time, improving their efficiency, and helping them keep opportunities alive.

Ito Group has a unique set of technologies and advantages that stem from 75 years of experience in manufacturing and electronics assembly. We use these technologies and advantages to build both standard and custom equipment for customers ranging from R&D labs to high volume factories running over 1KK assemblies/day.

ACF machine

Table-Top type

ACF laminator, model TTL-6010

Compact tabletop ACF laminator

The TTL-6010 is a tabletop ACF laminator designed to be used in production environments as well as prototyping labs. It laminates a single piece of ACF to a single site on a substrate that in turn is manually loaded and unloaded by the operator. It features a touch panel for setting lamination parameters and is extremely easy to use and maintain.

Additional Features:

- Highly-responsive PID controllers for temperature control.

- Precision air cylinder for fine pressure control.

- 600UPH (TYP).

- Maximum 60mm ACF lamination length.

- Maximum 10mm ACF lamination width.

- Designed for rapid tooling changeover.

- Floating CarrierTM capable.

- Comprehensive native English manual covering set-up, process development, maintenance, and operation. Other languages (Japanese, Chinese, Vietnamese, etc.)

Table-Top type,

ACF Final bonder, model TTAB-1008CR

ACF aligner-bonder

The TTAB-1008CR/2525AR is a tabletop ACF (anisotropic conductive film) aligner-bonder featuring a rotary table for improved throughput. It is available in both constant heat and ActiveHeatTM configurations and features a unique stage support mechanism which improves coplanarity and allows the machine to be used with complex 3D structures such as camera modules.

The TTAB-1008CR/2525AR is designed to manually align a single device to a single substrate by using micrometers and a set of cameras and displays. The device can range from a simple flexible printed circuit to a complete display assembly or camera module. After alignment has been completed, the operator presses the START buttons and the machine stage rotates so that the aligned assembly can be bonded while a second assembly is prepared. Load, unload, and alignment are all performed by the operator.

The TTAB-1008CR/2525AR is recommended for use in FOG, FOB, and FOF assembly and has a recommended minimum pitch of 0.2mm when using a 0.1/0.1mm line/space configuration.

Additional Features:

- Highly-responsive PID controllers for temperature control.

- Precision air cylinder with digital pressure regulator for fine pressure control.

- Rotary stage for high throughput and efficiency (TYP 300UPH).

- Designed for rapid tooling changeover.

- Floating CarrierTM capable.

- Comprehensive native English manual covering set-up, process development, maintenance, and operation. Other languages (Japanese, Chinese, Vietnamese, etc.) available upon request.

General Specifications:

| TTAB-1008CR | TTAB-2525AR | |

| Heating Method | Constant Heat | Ceramic ActiveHeat™ |

| Heat Tool Size | Length: 5-100mm – Width: 1-8mm | Length: 5-25mm – Width: 1-25mm |

| Power | AC100 – 240V, Single Phase | |

| Product Size Range | W100mm x L150mm (Center Bonding Position) | |

| Substrate Stage | 2 Interchangeable Stages – Max W100 x D120mm | |

| Device Stage | 2 Interchangeable Stages – Max W150 x D100mm | |

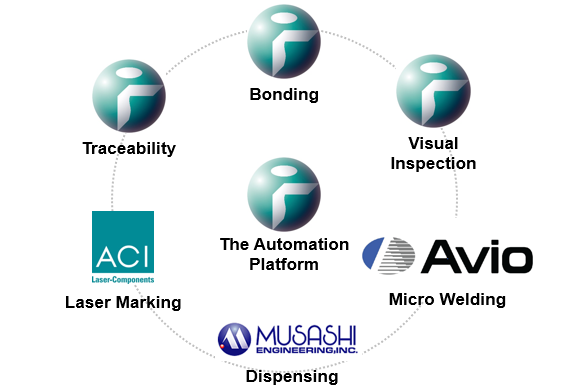

VSTAR-High Precision Electronics Assembly Platform

The V-Star Platform is a FLEXIBLE and GENERAL-PURPOSE automation platform for electronics manufacturing, especially smartphone assembly. Changeovers for other purposes are very easy, and extra features can be quickly added.

Key Technology Features:

- Micro joining

- Micro welding

- Micro dispensing

- Multi-material laser marking

- High-precision movement

- High-precision vision

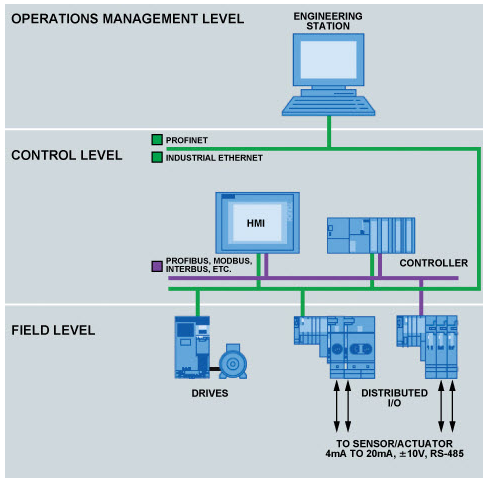

Below are how it works and how it benefits your factory in electronics manufacturing management.

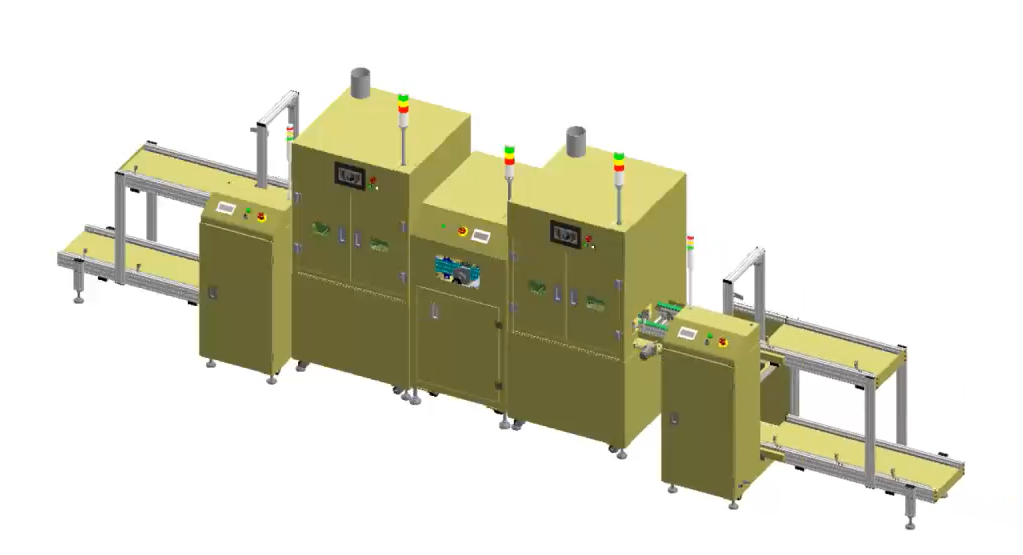

1) Every machine in the V-Star automation platform is able work as a standalone machine and they can also be connected together as one fully automated line for electronics production:

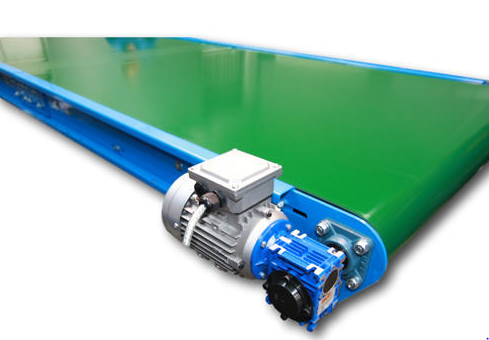

- The transportation method for products between machine-to-machine driven by Conveyor system

- The actual machine stage is driven by high-precision XY motors which ensure the high-quality at the output.

- The head unit (with or without rotation) is designed independently to be detached, and replaced by a new head

- The head unit is flexible and can be integrated with many types of actuators, and equipment (such as cameras for visual inspection and vision system, barcode readers for traceability, etc)

- The head unit can also be integrated with other technologies from third parties; such as AVIO welding head, MUSASHI dispensing head, ACI laser marking head, HAKKO Soldering head, etc.

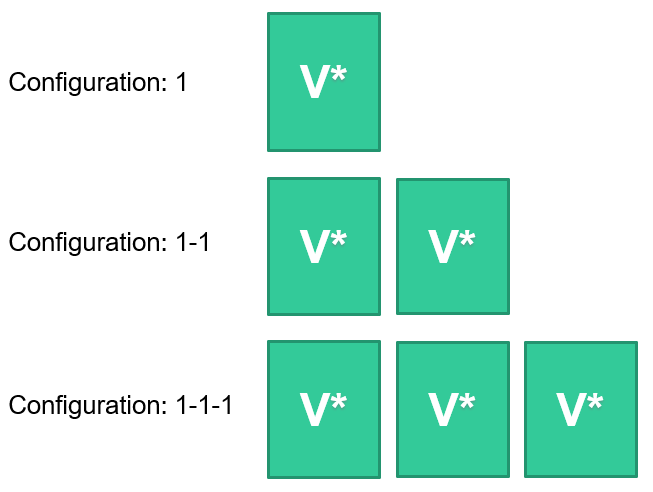

2) Flexibility in production line configuration; such as 1, 1-1, 1-1-1, 1-1-1-1 or any configuration what is suitable for your output requirements.

3) Connect to other makers’ machines via standardized communication protocols and standardized conveyor system; such as Ethernet TCP/IP, CC-link IE Field, Modbus, Serial.

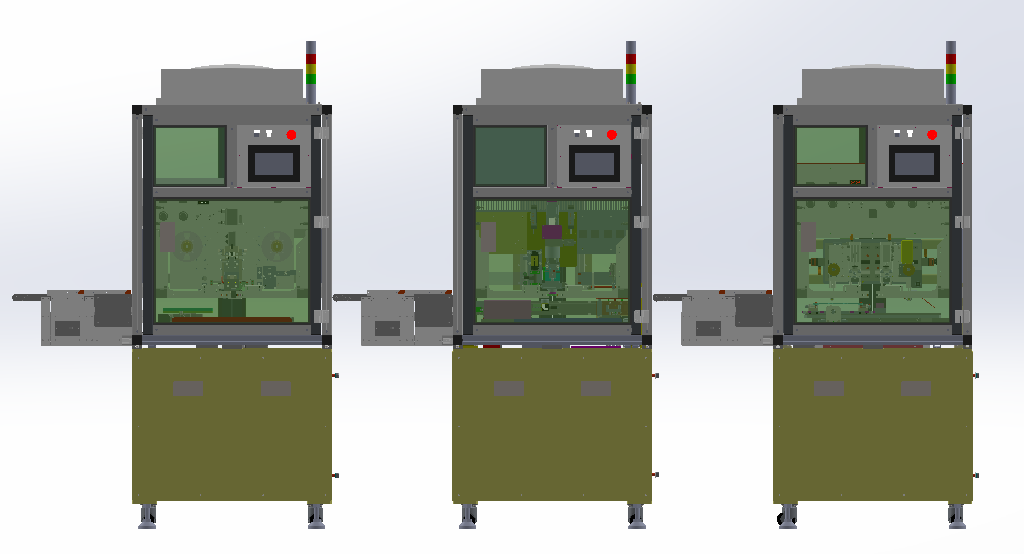

4) There are 3 general purpose platforms in the V-Star line-up. Depending on each manufacturing purpose and desired quality, you can decide which platform you would like to use; 2-axes, 3-axes or 4-axes.

- V2-3030: general purpose 2-axes platform

- V3-3030: general purpose 3-axes platform

- V4-3030: high-precision 4-axes platform

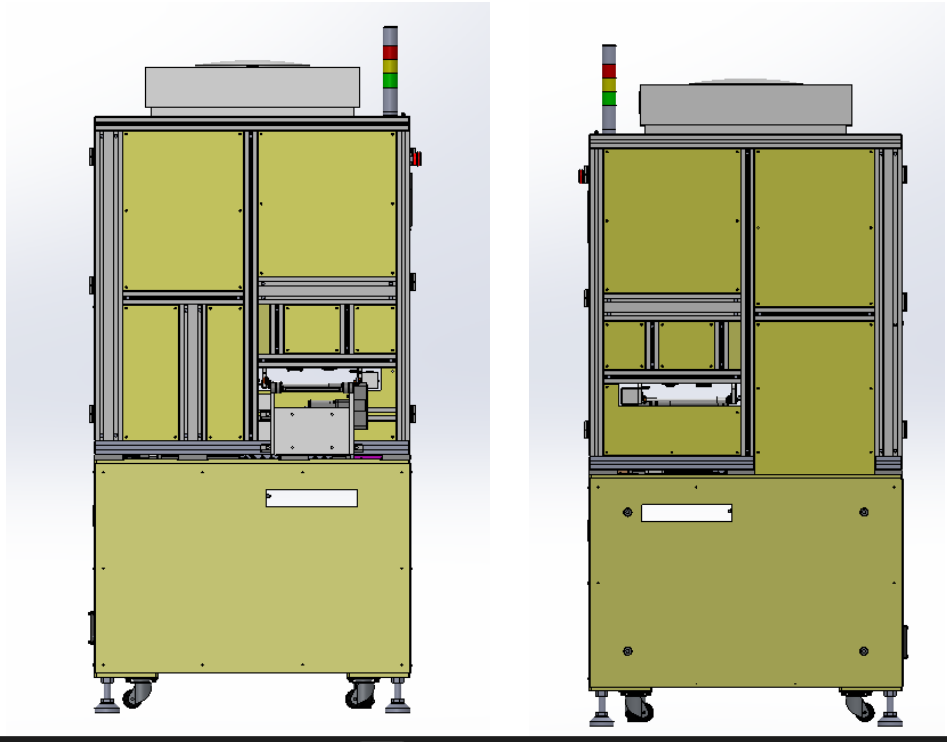

The V-Star automation platform – Front view

The V-Star automation platform – Left / Right view