Intelligent Meglev Transport Technology

iTS (Intelligent Transport System)

Shanghai Golytec Automation Co., Ltd. was established in 2015 featuring a powerful R&D and manufacturing center. It focuses on the research and innovation of Maglev Drive transport technology and is a leading intelligent and flexible transport system solution provider in the industry.

Golytec adheres to the principle of “customer first, continuous innovation, excellent quality, and outstanding service” in its supply of precision, high-speed, and intelligent Maglev Drive transport system products and services to equipment suppliers, manufacturers, and partners in industries such as lithium batteries, 3C consumer electronics, semiconductors, LCD panels, automotive electronics, medical devices, pharmaceuticals, intelligent logistics, and high-end consumer goods worldwide.

Golytec has obtained certifications on product safety and environmental protection such as CE and RoHS, and quality management system certifications such as ISO9001. In 2018, it was recognized as a “high-tech Enterprise” by the Shanghai Municipal Government. In 2022, it was rated as a “specialized and innovative” enterprise in Shanghai. In 2023, it was recognized as a pilot unit for enterprise and public patent promotion in Shanghai.

Shanghai Golytec Automation Co., Ltd. was established in 2015 featuring a powerful R&D and manufacturing center. It focuses on the research and innovation of Maglev Drive transport technology and is a leading intelligent and flexible transport system solution provider in the industry.

Golytec adheres to the principle of “customer first, continuous innovation, excellent quality, and outstanding service” in its supply of precision, high-speed, and intelligent Maglev Drive transport system products and services to equipment suppliers, manufacturers, and partners in industries such as lithium batteries, 3C consumer electronics, semiconductors, LCD panels, automotive electronics, medical devices, pharmaceuticals, intelligent logistics, and high-end consumer goods worldwide.

Golytec has obtained certifications on product safety and environmental protection such as CE and RoHS, and quality management system certifications such as ISO9001. In 2018, it was recognized as a “high-tech Enterprise” by the Shanghai Municipal Government. In 2022, it was rated as a “specialized and innovative” enterprise in Shanghai. In 2023, it was recognized as a pilot unit for enterprise and public patent promotion in Shanghai.

Family of Products: Quality, Safety, Reliability

Technical Highlights:

Comprehensive specification:

Standard loop, circular, rectangulat, track switching and diverting, etc.

Scalable, high precision

Applications:

Food packaging, 3C electronics, lithium batteries, cosmetics filling, medical devices

Technical Highlights:

Comprehensive specification:

Vertical transfer, horizontal transfer, and mixed transfer; high precision, cost effective

Applications:

3C electronics, lithium batteries, automative electronics

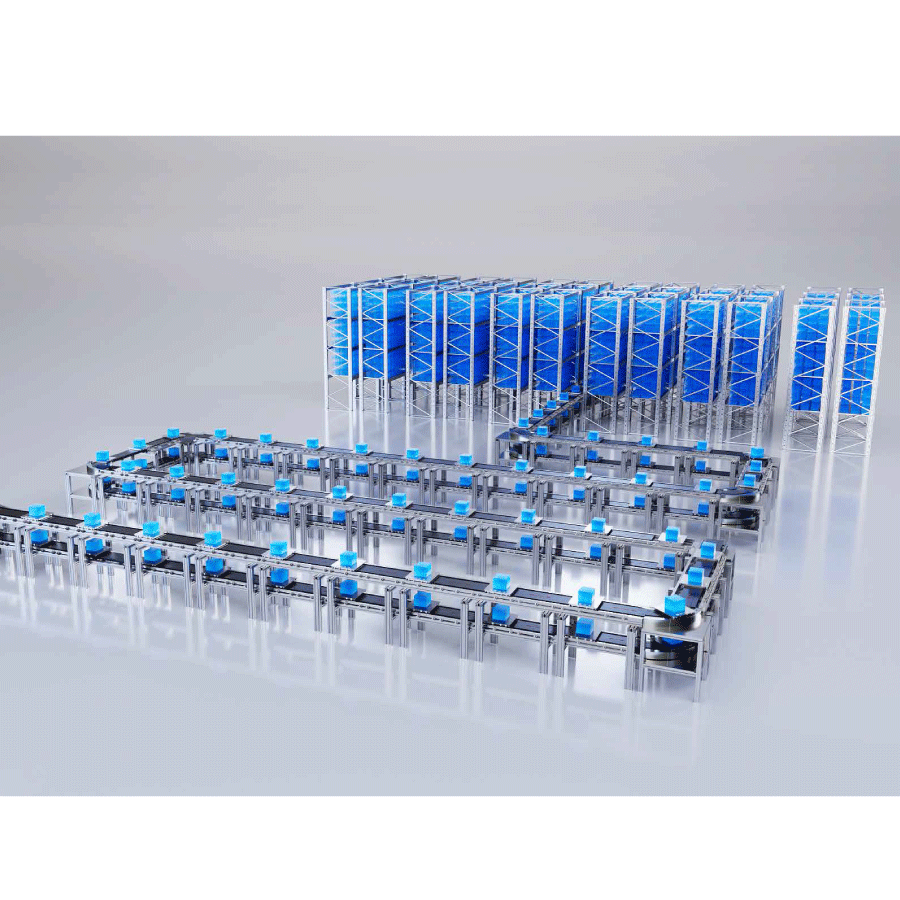

Technical Highlights:

Comprehensive specification:

Vertical return, rotary diversion, curved turns, cross-intersections, Z-lifts, etc.

Intelligent scheduling, high efficiency

Applications:

Warehousing & logistics, home appliance manufacturing, pharmaceutical production, daily consumables

Technical Highlights:

Comprehensive specification:

Extra-large load transport, high precision, high speed, low noise, low energy consumption, intelligent flexible sheduling, compliant with international functional safety standards

Applications:

Automative, heavy industry manufacturing, robot 7th axis

Technical Highlights:

Comprehensive specification:

High cleanliness, high speed precise positioning, dust-free operation, low vibration, modular design, energy-efficient, mature cross-industry applications, and supports various complex path forms such as linear, curved, and horizontal transfers

Applications:

Semiconductor, photovoltaics, LED, panels

Family of Products: Quality, Safety, Reliability

Technical Highlights:

Comprehensive specification:

Standard loop, circular, rectangulat, track switching and diverting, etc.

Scalable, high precision

Applications:

Food packaging, 3C electronics, lithium batteries, cosmetics filling, medical devices

Technical Highlights:

Comprehensive specification:

Vertical transfer, horizontal transfer, and mixed transfer; high precision, cost effective

Applications:

3C electronics, lithium batteries, automative electronics

Technical Highlights:

Comprehensive specification:

Vertical return, rotary diversion, curved turns, cross-intersections, Z-lifts, etc.

Intelligent scheduling, high efficiency

Applications:

Warehousing & logistics, home appliance manufacturing, pharmaceutical production, daily consumables

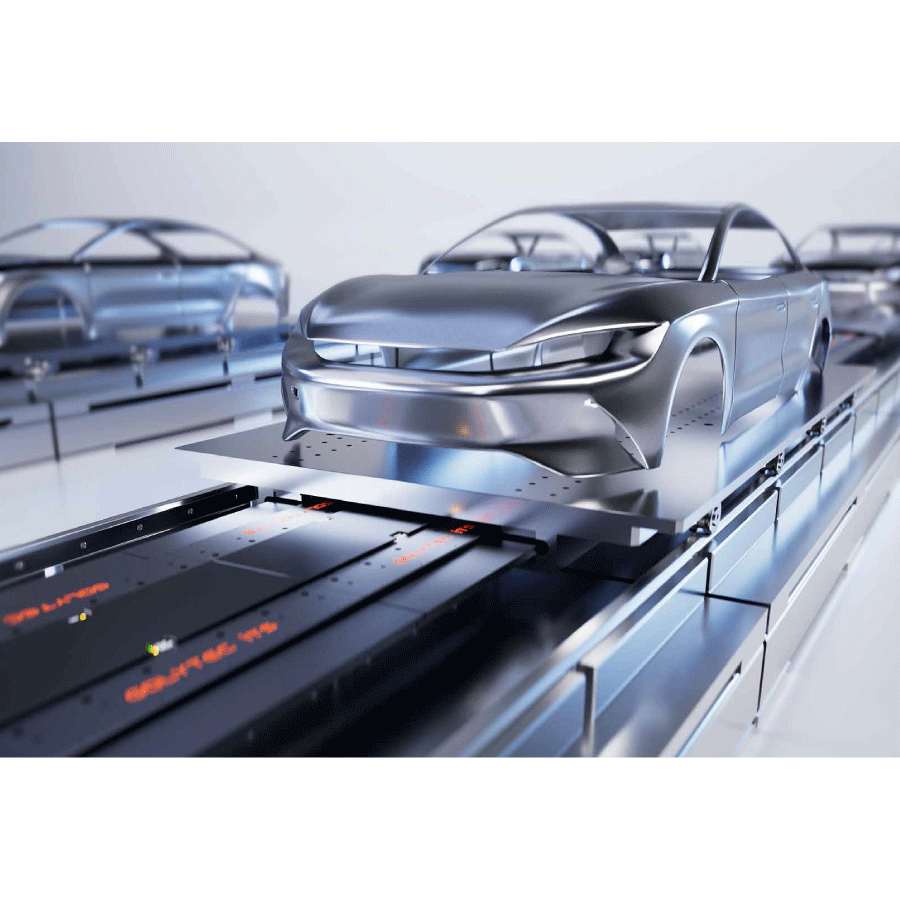

Technical Highlights:

Comprehensive specification:

Extra-large load transport, high precision, high speed, low noise, low energy consumption, intelligent flexible sheduling, compliant with international functional safety standards

Applications:

Automative, heavy industry manufacturing, robot 7th axis

Technical Highlights:

Comprehensive specification:

High cleanliness, high speed precise positioning, dust-free operation, low vibration, modular design, energy-efficient, mature cross-industry applications, and supports various complex path forms such as linear, curved, and horizontal transfers

Applications:

Semiconductor, photovoltaics, LED, panels

Family of Products: Quality, Safety, Reliability

Technical Highlights:

Comprehensive specification:

Standard loop, circular, rectangulat, track switching and diverting, etc.

Scalable, high precision

Applications:

Food packaging, 3C electronics, lithium batteries, cosmetics filling, medical devices

Repedtability ±0.03mm

Max Acceleration 5g

Payload 2kg-40kg

Max Velocity 6m/s

Technical Highlights:

Comprehensive specification:

Vertical transfer, horizontal transfer, and mixed transfer; high precision, cost effective

Applications:

3C electronics, lithium batteries, automative electronics

Repedtability ±0.001~0.01mm

Max Acceleration 5g

Payload 2kg-100kg

Max Velocity 6m/s

Technical Highlights:

Comprehensive specification:

Vertical return, rotary diversion, curved turns, cross-intersections, Z-lifts, etc.

Intelligent scheduling, high efficiency

Applications:

Warehousing & logistics, home appliance manufacturing, pharmaceutical production, daily consumables

Repedtability ±0.1mm

Max Acceleration 0.5g

Payload 2kg-500kg

Max Velocity 1.5m/s

Technical Highlights:

Comprehensive specification:

Extra-large load transport, high precision, high speed, low noise, low energy consumption, intelligent flexible sheduling, compliant with international functional safety standards

Applications:

Automative, heavy industry manufacturing, robot 7th axis

Repedtability ±0.1mm

Max Acceleration 1g

Payload 100kg-5000kg

Max Velocity 3.5m/s

Technical Highlights:

Comprehensive specification:

High cleanliness, high speed precise positioning, dust-free operation, low vibration, modular design, energy-efficient, mature cross-industry applications, and supports various complex path forms such as linear, curved, and horizontal transfers

Applications:

Semiconductor, photovoltaics, LED, panels

Repedtability ±0.3mm

Max Acceleration 2g

Payload 2kg-40kg

Max Velocity 5m/s

9 Key Usage Advantages

iTS Maglev drive Flexible Transport System

Ultra-High Efficiency

Mover speed can reach up to 6m/s, enabling rapid acceleration and micron-level positioning accuracy. In specific production processes, efficiency can be increased by 3 to 5 times.

High Precision

The mover repeatability can reach up to +/-0.001mm. Reduces the need for external positioning mechanisms, ideal for high-precision production processes.

High Cleanliness Level

Frictionless operation, no particulate dust, suitable for production processes with high cleanliness requirements.

High Flexibility

Cable-free movers (no drag chains) enable synchronous and asynchronous control. Production sequences and stations are software-configurable to match production pace and optimize workflows.

Low Maintenance Costs

The system's modular design ensures quick installation, repair, and rapid commissioning, significantly reducing installation and maintenance time and costs.

More Space-Saving

Reduces equipment footprint by over 40%. Supports co linear production and rapid product changeovers, further reducing costs and increasing efficiency for enterprises.

High Scalability

The system length can exceed 5,000 meters and accommodate over 5,000 movers. It also supports secondary line modifications and expansions.

Energy Conservation

Energy is consumed only where the movers operate, with no power used, thus saving energy.

Customization Options

Products can be customized for specific requirements such as waterproofing, dustproofing, and corrosion resistance, ased on the customer's application.

9 Key

Usage Advantages

iTS Maglev drive Flexible Transport System

Ultra-High Efficiency

Mover speed can reach up to 6m/s, enabling rapid acceleration and micron-level positioning accuracy. In specific production processes, efficiency can be increased by 3 to 5 times.

High Precision

The mover repeatability can reach up to +/-0.001mm. Reduces the need for external positioning mechanisms, ideal for high-precision production processes.

High Cleanliness Level

Frictionless operation, no particulate dust, suitable for production processes with high cleanliness requirements.

High Flexibility

Cable-free movers (no drag chains) enable synchronous and asynchronous control. Production sequences and stations are software-configurable to match production pace and optimize workflows.

Low Maintenance Costs

The system's modular design ensures quick installation, repair, and rapid commissioning, significantly reducing installation and maintenance time and costs.

More Space-Saving

Reduces equipment footprint by over 40%. Supports co linear production and rapid product changeovers, further reducing costs and increasing efficiency for enterprises.

High Scalability

The system length can exceed 5,000 meters and accommodate over 5,000 movers. It also supports secondary line modifications and expansions.

Energy Conservation

Energy is consumed only where the movers operate, with no power used, thus saving energy.

Customization Options

Products can be customized for specific requirements such as waterproofing, dustproofing, and corrosion resistance, ased on the customer's application.